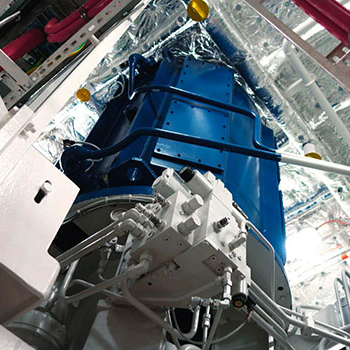

A_M - B_M

Technical Features

SERIES: A_M – B_M

POWER: Up to 2400kW

VOLTAGE: Up to 690 V

FRAME: 71mm to 560mm

POLE: 2 to 16

FREQUENCY: 50Hz, 60Hz or variable speed

PROTECTION DEGREE (IP): 55, 56, 65 (only cast iron)

COOLING METHOD (IC): 411, 410, 416

AMBIENT TEMPERATURE: -55°C to +60°C

ENCLOSURE MATERIAL:Aluminum (A5M-A6M) Cast iron (B5M-B6M)

BEARING: Antifriction, sleeve (from frame 355)

APPLICATIONS: Auxiliaries, Fi-Fi system, Winch

STANDARD / CERTIFICATE: IEC 60034

Main Options:

- PT100 in stator windings

- Anti-condensation heaters

- Special voltage

- Arrangement for vibration sensors

- Insulated bearing and earthing brush

- Lubrication system for sleeve bearing