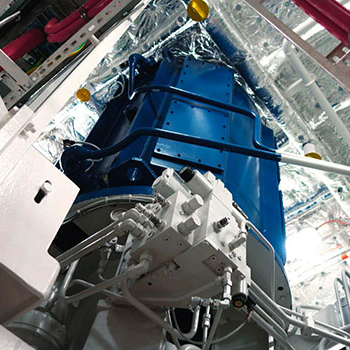

C3G - C4G

Technical Features

SERIES: C3G, C4G (low voltage) C3GH, C4GH (medium voltage)

POWER: Up to 3400kW

VOLTAGE: Up to 6600 V

FRAME: 280 to 710

POLE: 2 to 16

FREQUENCY: 50 Hz, 60 Hz or variable speed

PROTECTION DEGREE (IP): IP23

COOLING METHOD (IC): 01, 06

AMBIENT TEMPERATURE: -20°C to +60°C

ENCLOSURE MATERIAL: Welded steel

BEARING: antifriction, sleeve (from frame 355)

APPLICATIONS: Cross-Flow turbines, Francis turbines, Kaplan turbines, Pelton turbines, Turgo turbines

STANDARD / CERTIFICATE: IEC 60034

Main Options:

- PT100 in stator windings

- Anti-condensation heaters

- Special voltage

- Arrangement for vibration sensors

- Insulated bearing and earthing brush

- Horizontal or vertical shaft design

- Neutral point terminals in separate terminal box

- Lubrication system for sleeve bearing

- Inlet and outlet filters for increased protection degree up to IP44

- Arrangement for air duct system to convey inlet / outlet cooling air

- Bearings arrangement suitable for high axial and radial forces coming from the turbine

- Special shaft end for direct coupling with turbine

- Additional flywheel for dedicated inertia value

- Brake system

Downloads

-

-

Marine Product catalogue