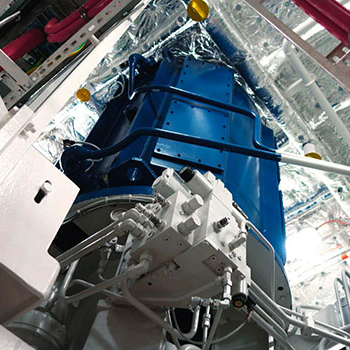

MXB-E

Technical Features

SERIES: MXB-E

POWER: Up to 375 kVA

VOLTAGE: Up to 690 V

FRAME: 160 – 250

POLES: 4

FREQUENCY: 50/60 Hz

PROTECTION DEGREE (IP): 23 (up to 44 on request from 180 to 250 frame size)

COOLING METHOD (IC): 01

AMBIENT TEMPERATURE: -15°C to +60°C

AVR: Mark VX

BEARINGS: Antifriction

APPLICATIONS: Power Generation, Cogeneration, Stand-by/Emergency, UPS, Data center, Portable

STANDARDS: IEC 60034-1 – BS 4999-5000 – NEMA MG 1.32

CERTIFICATIONS: UL 1004-1, UL 1004-4, C22.2 No. 100

Main Options:

- Special voltage

- Provision for parallel operation with similar generators

- IP55 terminal box

- Anti-condensation heaters

- PT100 in stator windings

- Inlet and outlet filters for increased protection degree up to IP44

- Auxiliary winding for AVR power supply and overboosting

- Excitation/overboosting PMG mounted on generator

Downloads

-

-

Marine Product catalogue